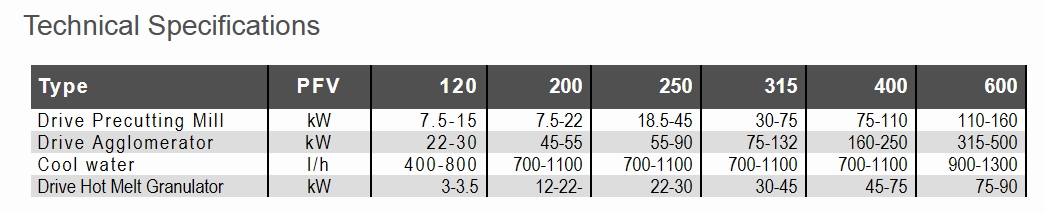

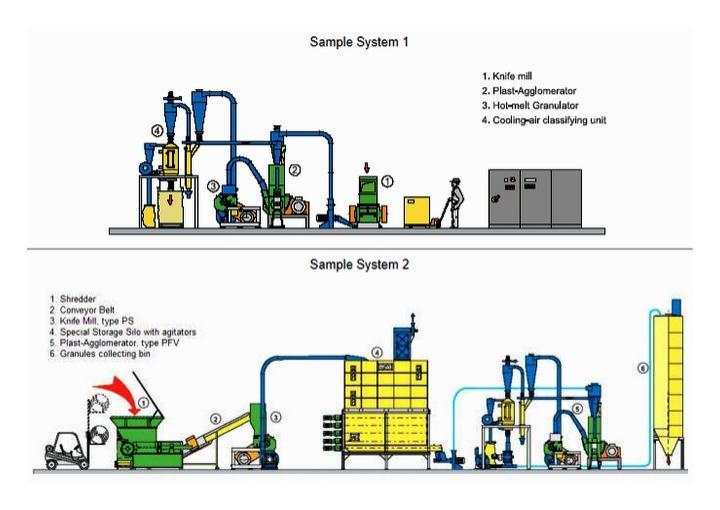

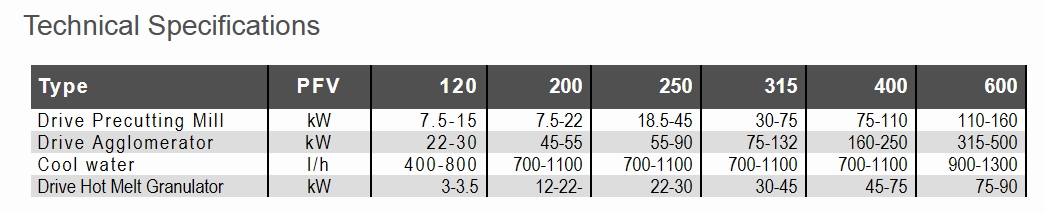

During the production and processing of thermoplastics, production waste occurs which can be agglomerated continuously with the PALLMANN Plast-Agglomerator into free-flowing granules and reused for production as valuable raw material. All thermoplastic materials such as PE, PP, PS, PA, PET, PVC, ABS, XPS, PLA and composite materials of any kind, in the form of bulky film, fiber, or foam waste, can be continuously recycled with the same system. The standard Plast-Agglomerator system consists of the following processing steps: Pre-cut, Pneumatic conveying, Storing, Feeding, Agglomerating, Hot-melt granulating, Pneumatic Conveying, Pre-cooling, Air classifying, Transport, and Cooling.

Advantages & Features

| Continuous process

|

| Excellent free-flowing agglomerate with high bulk density

|

| Material-gentle agglomeration by means of frictional heat

|

| Minimum thermo-degradable damage

|

| Fully automatic start from a cold condition

|

| Low space requirement due to compact design

|

| Fully automatic continuous operation

|

Applications

Production of free flowing granules from thermoplastic materials of all kind such as: